Wastewater and Sewage Treatment

Today’s Technology Solutions

Wastewater treatment hasn’t changed much in the past 50 years. For biological based treatment, there are variants, but they are all based on aerobic and anaerobic processes.

Aerobic Processes

Biologically treating wastewater requires oxygen to fuel decomposition. The bigger your facility and the more wastewater streams you create, the more oxygen the on-site treatment facility will need; otherwise, treatment will either slow down or require an increase of power and overall time to process said waste. Both of these result in the overall system decreasing its efficiency, thereby increasing costs.

Anaerobic Digestion Systems

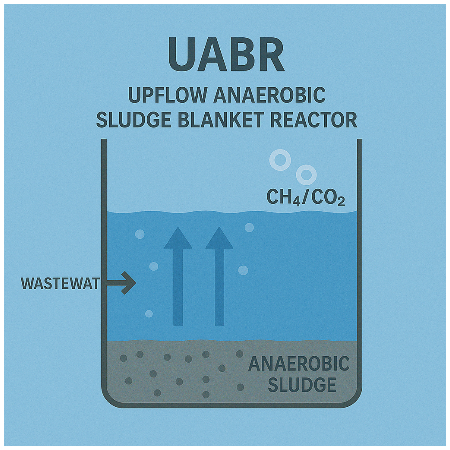

Anaerobic digestion uses microbial communities to remove organic matter without oxygen. Fun fact: while there have been many advances since then, the first anaerobic digester was actually installed in India in 1859 in a leper colony.

Many modern wastewater treatment facilities use anaerobic digestion in some form. A low-cost form of anaerobic digestion is the use of anaerobic ponds in which wastewater is dumped into a hole as it would be in a landfill and left fully to biological processes to solve. However, agricultural industries and large industrial plants have more commonly incorporated anaerobic digestion because of the significant side-benefit of generating a type of methane known as biogas which can be captured during the treatment process and used as an energy process.

Because the system itself creates and captures energy, anaerobic digestion systems offer sustainability benefits to companies, as the biogas can offset power demand for the facility and help meet greenhouse gas commitments.

Mahsab Shargh Engineering Company offers sanitary and industrial wastewater treatment services in the following categories.

Wastewater Treatment Projects:

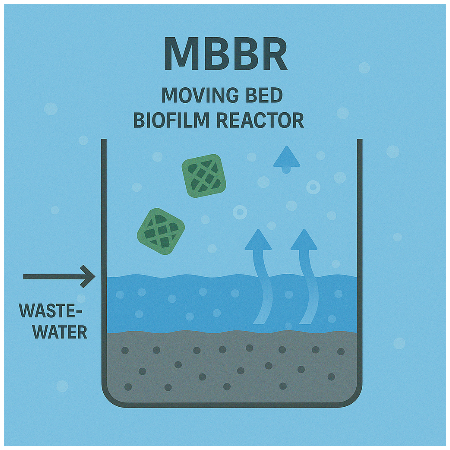

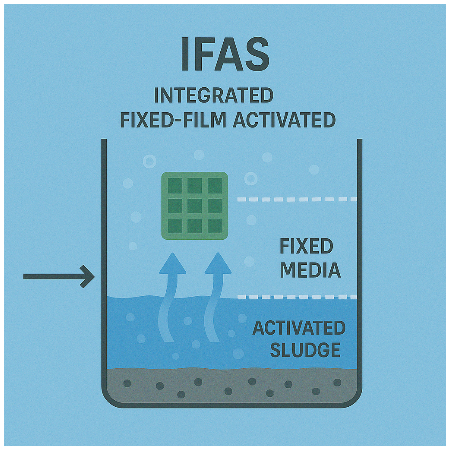

- Design and implementation of biotechnological processes for industrial wastewater treatment, including MBBR/IFAS/UABR processes

- Design and implementation of aerobic and anaerobic biofilm processes and suspended growth bioreactors

- High-rate biological processes in addition of biotechnological enzymes

- Treatment of high-pollution industrial wastewater

- Upgrading the capacity and quality of treatment in existing wastewater treatment plants

- Heavy metal removal processes

- Prefabricated, portable packages suitable for small communities, available in two types: Ultra-advanced type (This company is the representative of Fuji Clean Japan) and advanced aerobic packages.

- Advanced Oxidation Processes (AOP) for the removal of complex organic and biological compounds.

Oily Wastewater Treatment

Treatment systems vary based on the characteristics of the effluent. This company has the capability to design and implementation of the following systems for oil-water separation and the purification of oily wastewater:

- CPI Systems

- DAF Systems (Dissolved Air Flotation)

- IGF Systems (Induced Gas Flotation)

- Oil-Water Separation Processes using resin beds/media

- Adsorption with absorbent filters (Activated Carbon and specific absorbents)

Water Reclamation and Reuse:

- Design and construction of wastewater treatment plants with the goal of water reclamation for industrial or potable purposes

- Design and integration of advanced wastewater treatment technologies, such as Membrane Bioreactors (MBR system)

- ZLD (Zero Liquid Discharge) processes and 100% water recycling for reuse

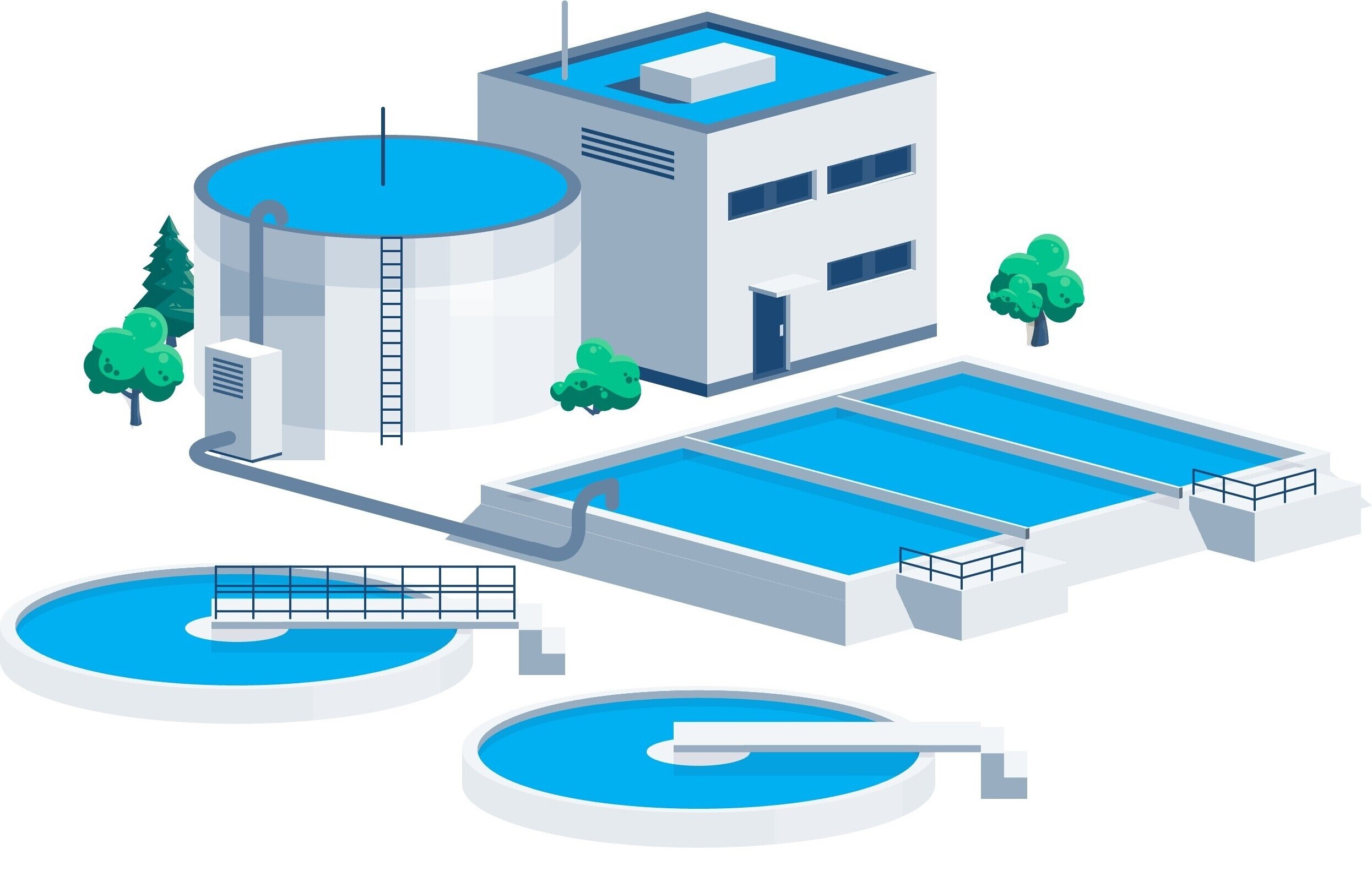

A View of the Farahzad Project Treatment Plant