Wastewater Treatment Using the UABR Method

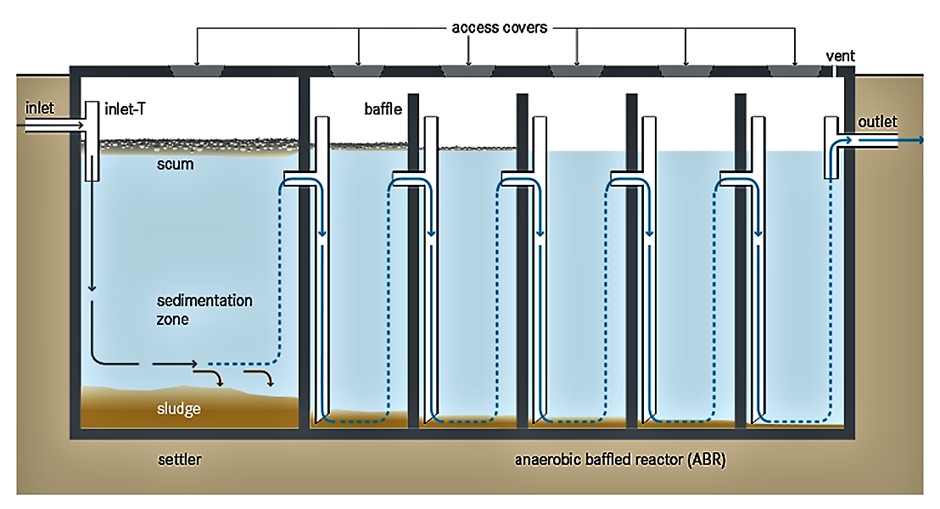

The UABR system (Up flow Anaerobic Baffled Reactor) is an up flow anaerobic reactor used for wastewater treatment. This system utilizes a series of baffles to direct wastewater flow upward and into contact with biological sludge, resulting in the anaerobic digestion of organic matter in the wastewater.

Main Components of the UABR System:

Baffles:

These baffles direct the wastewater flow in an upward direction, increasing the contact time between the wastewater and biological sludge.

Biological Sludge:

This sludge consists of anaerobic microorganisms that digest the organic matter present in the wastewater.

Separate Chambers:

The UABR system comprises multiple separate chambers that help modulate environmental conditions such as pH and temperature, while controlling hydraulic and organic shocks.

Advantages of the UABR System:

High Efficiency:

The UABR system is capable of treating a wide range of wastewater types with high efficiency.

High Pollution Load Tolerance:

This system can withstand high pollution loads, and variations in these parameters have minimal impact on its performance.

Low Energy Consumption:

As the system operates anaerobically, its energy consumption is very low.

Suitable Stability:

The UABR exhibits appropriate stability against hydraulic and organic shocks.

No Need for Solids Separation:

This system does not require equipment for separating settled solids.

Applications of the UABR System:

Treatment of industrial wastewater

Treatment of domestic wastewater

Treatment of wastewater from food, pharmaceutical, and paper industries

Production of biofuels (biogas) in high capacities

Disadvantages of the UABR System:

Requires further treatment of effluent and residual sludge for reuse or direct discharge into the environment